Squash Floors

International standard Squash Floors

In fast paced games like squash and racquetball, the squash floor should give the player freedom of movement, optimal ball bounce and protection against injuries. A solid beech floor has proved itself to be the best option in preference to all the other types of floor that might be used for squash courts.

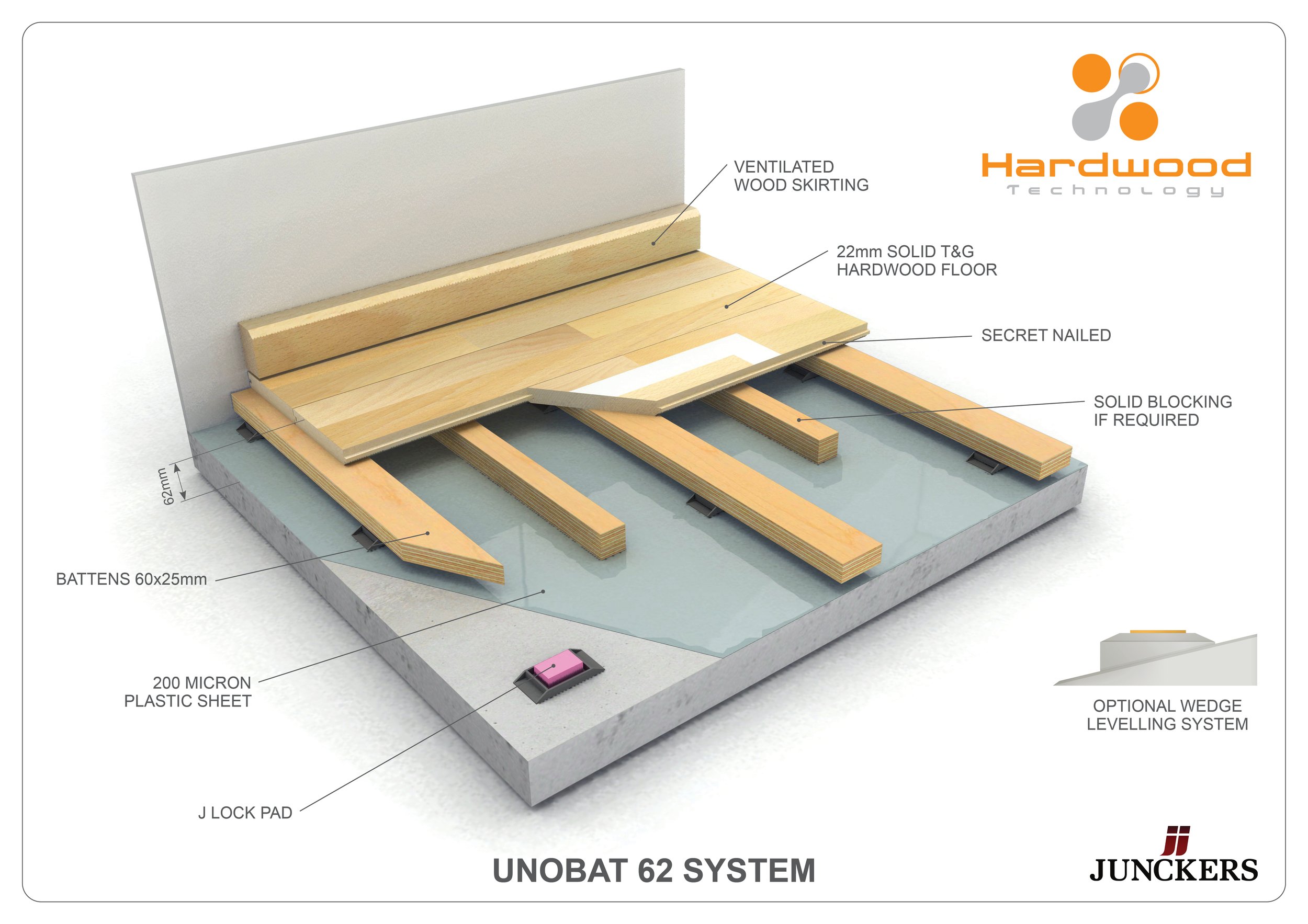

While the surface of the squash floor is important, what is also vital to a squash floor is what goes underneath. The undercarriage system has a direct bearing on the performance of the floor.

Our squash floor complies with EN 14904 cat A3 or A4, as well as the technical requirements of World Squash Federation. The floors meet defined limits for shock absorption and surface deflection, along with standards relating to safety and technical properties including friction, rolling load, vertical deformation, shock absorption and ball bounce.

| Use |

|---|

| Squash and Racquetball |

| Beginner to Professional |

| From small leisure centres to large arenas |

| Refurbishment |

Our Squash Floor Features

Junckers unique press drying process makes our squash floor very strong and results in a wooden floor that is inherently stable throughout the natural cycle of humidity changes during the year. In order to ensure a high level of ‘grip’ our floorboards are unsealed and have a slightly roughened surface, which provides the right level of friction whether the surface is wet or dry, keeping risk of injury to an absolute minimum. In addition, we offer the following key benefits:

EN 14904 Standard Compliant

All Junckers’ sports flooring systems have unique area elastic properties to ensure optimal shock absorption in accordance with the European EN 14904 standard. This means Junckers’ floors are proven as suitable for squash courts at the highest level.

Point Load & Fatigue Tested

In addition to the European standard, Junckers has added two further internal tests to demonstrate the strength and longevity of their floors. A fatigue test where the floor is exposed to a series of controlled, dynamic point impacts of 300kg no less than 100,000 times, which simulates the equivalent of 25 years of normal use, and a point load test.

Optimal Longevity

Not only is our squash floor one of the safest and best performing wood floors on the market, they can be sanded between eight and ten times during their lives. In terms of life cycle cost and investment value this makes them unbeatable.

Examples of Squash Floors in use

Is our Squash Floor the right solution for your project?

If you’d like to understand the various features our Squash Floors can provide, please connect with the Hardwood Technology team – we’re here to help you get a great flooring solution and are only too happy to help you with valuable advice from our decades of experience.

About Junckers Sports Floorboards

Junckers’ sports floors are made from 100% solid hardwood and will last for generations. Each floor board is made from two rows of staves and is tongue and groove jointed all round.

The floors are extremely stable and therefore cause no challenges when humidity levels change through the year. Junckers take far longer than normal over the drying process to ensure that the movements that occur naturally in all wood is fully controlled and kept to a minimum. Beech sports floors are dried using Junckers’ unique press drying method. Ash and maple sports floors are kiln dried.

Junckers’ floors are ready to use as soon as they are fitted. This is because the floors are sealed in the factory with Junckers’ own hard wearing polyurethane lacquer.

All Junckers solid hardwood sports floors have the Danish Indoor Climate Certificate for low emissions of organic substances and can be delivered with either a FSC® or PEFC™ accreditation.

Each floor board has a length of 3700mm and covers approx. 0.5 m².